Best Apple Travel Accessories for Staying Connected on the Go

Explore top Apple travel accessories designed to keep your devices charged, connected, and efficient...

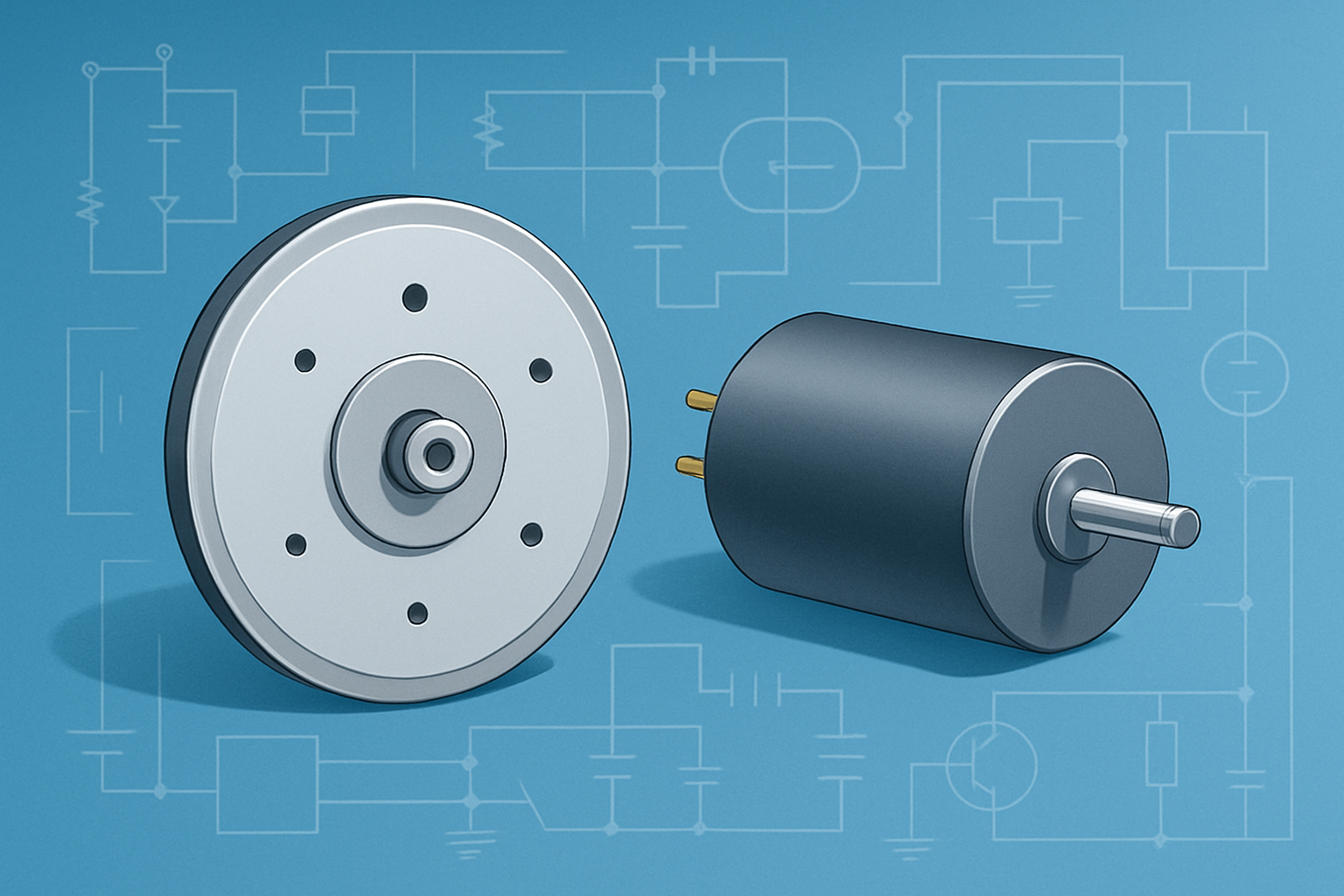

Pancake motors, sometimes called axial flux motors, stand out from traditional electric motors because of their distinctive flat disc-like shape and clever internal design. Unlike the usual cylindrical long motors you often see, pancake motors have a short axial length and a large diameter. This shape lets them deliver high torque while staying compact. It is a real win when space is limited but you need serious power density.

The term pancake motor got its name from its shape—flat and round like a pancake fresh off the griddle. Unlike typical cylindrical motors, these pancake motors spread their parts, the stator and rotor, across a wide flat plane.

Traditional electric motors such as brushed DC, brushless DC (BLDC) and induction types generally stick to a radial flux design. This means they are built with a cylindrical shape. In this setup the stator snugly wraps around the rotor in a concentric fashion with magnetic flux shooting outward from the center in a radial pattern.

The key difference really boils down to their shape and how the magnetic flux is arranged. Pancake motors feature an axial flux design that gives them a flatter and wider profile with the rotor and stator as parallel discs—like two frisbees stacked together. Regular motors use a radial flux setup with cylindrical rotors and stators. These design quirks greatly affect the motor's size, weight, torque and heat management.

| Feature | Pancake Motor | Regular Motor |

|---|---|---|

| Shape | Flat and disc-shaped, boasting a wide diameter that catches the eye | Typically cylindrical or tubular, nothing too flashy but reliable |

| Magnetic Flux | Axial flux, running smoothly parallel along the shaft | Radial flux, running perpendicular to the shaft, doing its thing quietly |

| Axial Length | Noticeably short, packing power in a compact form | Usually longer than the diameter, stretching out a bit more |

| Torque Density | Delivers impressive torque at lower speeds, a bit of a strong and steady type | Provides moderate torque but plays best when revving at higher speeds |

| Cooling Efficiency | Generally cools down better thanks to a larger surface area, like a breeze on a hot day | Cooling can be a mixed bag, often limited by its snug and compact design |

| Complexity | More intricate winding and assembly, definitely not a walk in the park to build | Simpler construction, more straightforward and standard fare |

| Typical Applications | Popular in robotics, aerospace, and compact actuators where space is tight but performance matters | Commonly found in household appliances, automotive, and good old industrial machinery |

| Speed Range | Usually sticks to a lower maximum speed because of its rotor design, trading speed for torque | Can reach higher max speeds, built for those moments when you really need to zoom |

Pancake motors offer many perks that really click in specialized fields. They’re known for producing impressive torque right from the start at low speeds thanks to their wider diameter and axial flux design. Their flat profile is a lifesaver when working with tight spots where you don’t have the luxury of extra length. A cool bonus is the large exposed surface which helps dissipate heat and keeps the motor cool during marathon runs.

Pancake motors definitely bring some solid benefits to the table, but they’re not without their quirks. Their manufacturing involves some pretty intricate winding patterns and a good deal of careful assembly, which usually means the production costs tend to climb a bit. Then there’s the large rotor diameter adding to rotor inertia, so hitting the high speeds that standard motors can manage is often out of reach. These motors aren’t exactly lining the shelves everywhere, which can narrow your options and sometimes lead to longer wait times.

Pancake motors truly shine in situations where you need a compact design that doesn’t skimp on strong torque or precise control. In robotics, they’re often the go-to choice for joint actuators when every bit of space and ounce of weight counts. Medical devices benefit from their silky smooth and pinpoint-accurate movements which make tricky tasks look almost effortless. In aerospace, these motors are trusted to handle flight surfaces and other actuator duties with reliable finesse.

Comparison visualization of a pancake motor and a regular cylindrical motor highlighting their distinctive flat versus cylindrical forms.

Choosing the right motor really boils down to what your application needs. You’ve got to think about space constraints and how much torque and speed you want. Of course, your budget is always in the back of everyone's mind. Pancake motors usually shine in tight spots where high torque at low speeds is the goal. On the flip side, traditional motors pull ahead for high-speed needs and tend to be easier to find.

Recent strides in materials like high-performance magnets and lightweight composites are quietly transforming pancake motors, making them not just more efficient but surprisingly compact too. Thanks to clever manufacturing techniques—think laser winding and modular assembly—the price tags are starting to look a bit friendlier. Toss in smart sensors and power electronics, and you get real-time control and diagnostics that are pretty slick in action.

Pancake motors are really shaking things up in the world of compact electric drive systems. They pack a surprisingly high torque punch, deliver spot-on precise control, and keep their cool with effective thermal management—all wrapped up in a sleek, flat design. From what I’ve seen, this nifty technology is poised to make a huge impact across aerospace, robotics, and loads of other fields over the next decade or so.

25 posts written

As a fan of cultural anthropology, Magnolia uncovers hidden patterns in human societies, translating complex social dynamics into captivating articles for curious minds.

Read Articles

Explore top Apple travel accessories designed to keep your devices charged, connected, and efficient...

Unlock practical marketing strategies designed specifically for small teams. Learn expert tips to pr...

Disruptive technologies often catch companies by surprise, reshaping industries swiftly. Learn why t...

SEO success isn't instant. This comprehensive guide uncovers why SEO takes longer than expected and...

27 posts written

25 posts written

24 posts written